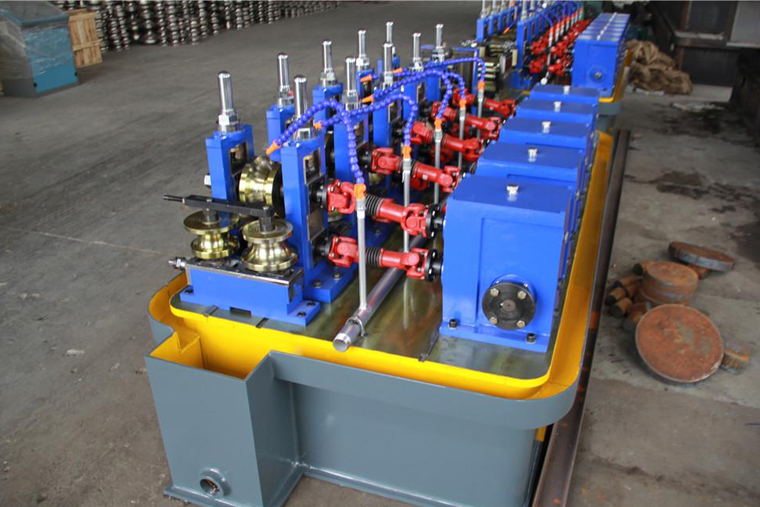

GMT supplies modern HFIW SS & ERW Tube Mills with most advance entry section, quick changing mill section, variety of flying cutoff machines and accurate tooling to meet the stringent requirements of general engineering, automotive, cross country pipe lines, structural, boiler, heat exchanger and other relevant applications.

GMT also supplies various tube finishing equipment like End Facing, Threading, Straightening, Hydro testing, Pointing, Drawing & Automatic Bundling etc.

The Tube Mills are robust in design, employ highly efficient helical drive system and various levels of automation to suit customer’s requirements. The special shaping stands and Turks head ensure complex hollow section production with precise quality. Cutoff machine can be selected according to productivity & application like Metal Saw Cutoff/ Press Cutoff.

Toolings are made of special tool steel to achieve maximum wear resistance and greater life.

GMT provides complete services start from project engineering right up to commissioning, startup & initial production assistance and after sales services.

| Model | TUBE OD (mm) | TUBE THICKNESS (mm) | MAX. LINE SPEED (M/mm) | |||

|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | Low Speed | High Speed | |

| GMT 1.5 | 10.0 | 38.1 | 0.5 | 2.6 | 60 | 100 |

| GMT 2 | 12.7 | 50.8 | 0.6 | 3.2 | 60 | 100 |

| GMT 3 | 15.88 | 76.2 | 0.8 | 3.6 | 60 | 100 |

| GMT 3.5 | 21.3 | 88.9 | 1.0 | 5.5 | 50 | 80 |

| GMT 4.5 | 33.4 | 114.3 | 1.2 | 6.0 | 50 | 80 |

| GMT 5 | 42.4 | 127.0 | 1.6 | 6.5 | 50 | 90 |

| GMT 6.5 | 60.3 | 168.3 | 2.0 | 7.1 | 40 | 70 |

| GMT 8.5 | 88.9 | 219.3 | 2.8 | 9.5 | 20 | 35 |

| Automatic Entry Lines | UP to 1200 mm Wide x 10 mm Thick x 25T coils x 450 m/min |

|---|---|

| H.R./C.R. Slitting Lines | Up to 2200 mm Wide x 12 mm Thick x 40T coils x 100 m/min. |

| Straightening Machines | UP to 165 mm OD x 7 mm Thick x 12 M long. |

| End Facing Machines | UP to 220 mm OD x 10 mm Thick x 12 m Long |

| Hydraulic Push Pointing Machines | Up to 140 mm OD x 15 mm Thick x 15 m Long |

| Single/Multi Tube Draw Benches | Up to 140 mm OD x 60 T force x 15 m Long |

| Single/Triple Tube Hydrotester | Up to 220 mm OD x 15 mm Thick x 15 m Long x 350 Bar pressure. |

| Threading Machines | Up to 165 mm OD x 12 m Long |

| Bundling Machines | Up to 165 mm OD x 12 m Long |