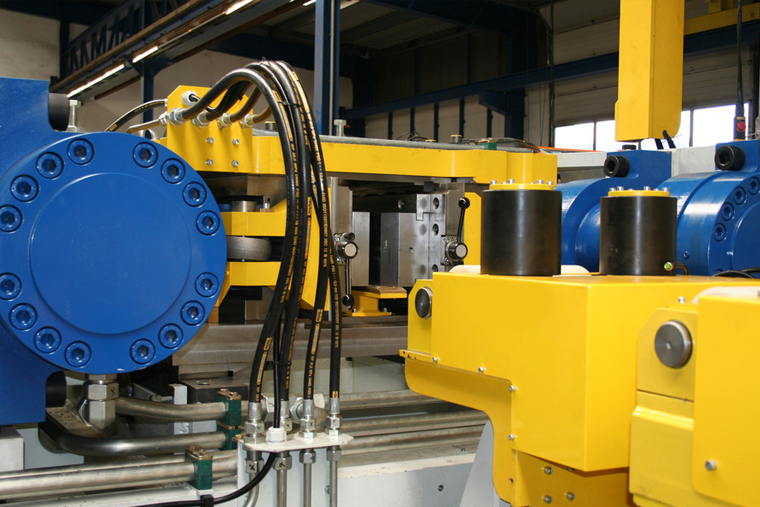

GMT Tube Push Pointer Machine is hydraulically operated for PUSH POINTING Tubular product prior to cold drawing. The Machine can handle Tubes having diameter 12 mm. O.D. minimum to 140 mm. O.D. maximum, both in Ferrous & Non-Ferrous material. Large size machines can also be offered. The conventional method of swaging is not only noisy & time consuming, but also produces inaccurate & irregular shaped points.

GMT Machines does the pointing with far more ease. It can produce points in four different length upon a maximum of 250 mm. The machine is also capable of Nozzeling the point from 50 to 75 mm. This machine is supplied along with a suitable handling system. The machine office many advantages over the conventional swaging/squeeze operations.

| Model | Max. Push Force | Max. Tube OD. |

|---|---|---|

| GMT-TPP 50 | 50,000 Lb | 88.9 mm |

| GMT-TPP 75 | 75,000 Lb | 130 mm |

| GMT-TPP 75/150 | 75,000/1,75,000 Lb | 140 mm |